Giant steel structures protect the municipality of Root against floods

The river Ron flows almost in a straight line through Rontal, the Ron valley. Heavily channelled and straightened, the stream between Rotsee and Reuss has already led to flooding on multiple occasions. As part of a multi-stage project, this body of water is now being given more space – in a process that is breathing new life into it. But some of the flood defences and revitalisation measures really demand huge efforts.

It’s early in the morning on Monday, 29 August 2022, and the mood is one of excitement and anticipation. Since 6.00 a.m. the project team from Basler & Hofmann has been on site along with the employees from the other construction firms involved. As the sun rises higher, they are gradually joined by increasing numbers of curious onlookers. Word has spread in the municipality of Root in Lucerne/Switzerland that there will be something unique to see today. Three days ago, preparations got under way on the construction of a new replacement stream culvert under the industrial train track just before the confluence of the Ron and Reuss rivers. “First the existing stream had to be cleared out of the way and diverted. Then the tracks were removed and the railway embankment was dug off. Finally the trench for the new stream culvert was excavated and a level, compacted bed was created on which the new culvert will be placed today”, explains Marcel Lüthi, Water Project Manager at Basler & Hofmann.

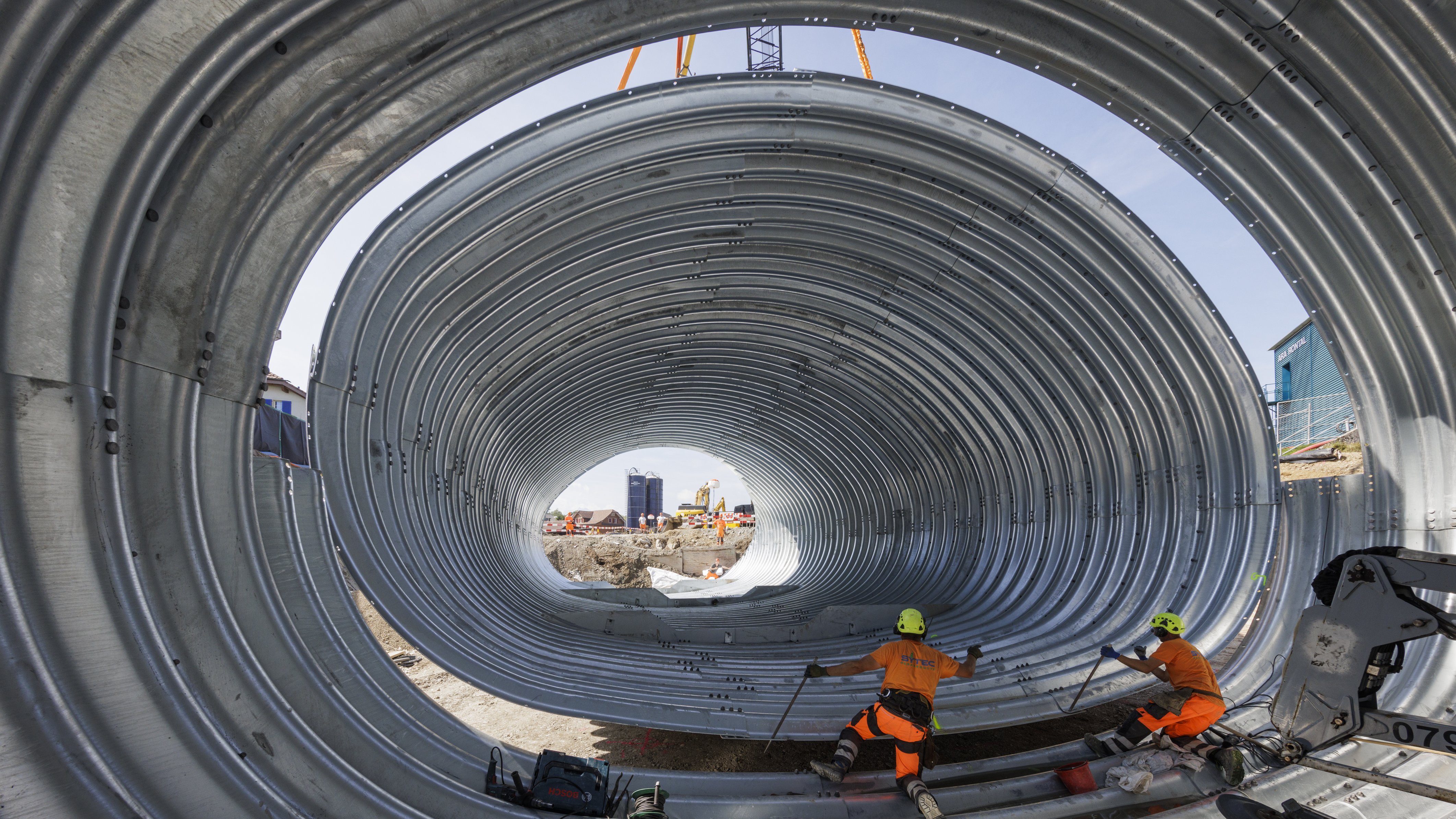

The new culvert is the first project of this magnitude in Switzerland. While the old culvert was a conventional concrete pipe, the new culvert has been built as a corrugated steel profile. “The advantage of this construction method is, in particular, the huge reduction in construction time, along with the use of less concrete”, emphasises Marcel Lüthi. “This method has already proved itself in practice. But nobody has been brave enough to do it underneath a railway line before. This is something we are pioneering together with the contractor.” At this point, the second of the three extremely heavy steel elements is dangling in mid-air from the crane. “The three elements were delivered in the last few days in the form of individual arched segments and then assembled on site”, says David Lotter, Site Manager for Hydraulic Construction at Basler & Hofmann.

Also on site is Sandra Erades, Site Manager for Bridges and Engineering Structures at Basler & Hofmann. “From a hydraulic point of view, the stream culvert is the biggest bottleneck in the project. This is why it is being dealt with first. At the same time we are also working on widening the first two bridges. But this spectacle today was not something I wanted to miss”, adds a beaming Sandra Erades. The perimeter of the full project extends beyond Root and also includes the municipalities of Dierikon, Buchrain and Ebikon. The contractor is the Canton of Lucerne. Construction work began at the start of 2022, and the measures are expected to be completed by the start of 2025. At this point the Ron is planned to have almost twice as much space, and the region will be protected up to a scale of a once-in-a-century type flooding event. By making the river profile and the banks of the stream more diversified, it is hoped that the river Ron will become an attractive habitat again for fish and other animals. The local population will benefit from new paths along the river banks, as well as from new communal spaces.

The process of installing the giant steel structures is already well under way. The biggest of these giants weighs a full 45 tonnes, with each of the smaller ones still adding slightly more than 20 tonnes each. The lightest element is placed at the furthest distance from the crane. An attempt to lift the heaviest element at this point could potentially risk toppling over the crane. The placement and connection of the three elements demand ultimate precision from the construction team. The workers use metal bars to grab the suspended element and guide it to the corresponding locating holes in the steel profile that has already been put in place.

At the same time, Marcel Lüthi and his team check that the stream retention is doing its job correctly and that no lowered groundwater penetrates into the trench. “Before a steel element is positioned by the crane, we use a special measuring device to check that the ground underneath has been sufficiently well compacted so that the whole thing remains stable afterwards and there is no subsidence”, explains Marcel Lüthi. Once the elements have been installed, gravel piled up on the sides is swept under the culvert with water. This ensures that there are no air pockets anywhere that could cause the giant steel structure to move. Then the bolted steel segments are covered layer-by-layer with highly compactable bulk material and the track system is restored above it.

According to Marcel Lüthi, there was another challenging aspect of this project that was somewhat “in the dark”. He is referring to the sewer tunnel, which carries all wastewater from the surrounding municipalities to the petrol-coloured buildings of the wastewater treatment plant next to the construction site. “The tunnel runs straight across underneath the culvert. If we were to damage the tunnel, this would potentially be a major problem. The water could penetrate into the construction site and cause environmental damage. But we have put safeguards in place in order to minimise this risk”, says Marcel Lüthi. “For one thing, we have ordered spare pipes to the construction site. In addition, pumps and pressure pipes have been installed in a shaft in front of the site, with which wastewater could be stopped and diverted if the worst came to the worst.”

Just five days after the three giant steel pipes were lifted in place the first train ran over the new culvert, with the stream taking up its new space underneath. The project team is delighted: «Together we have shown that corrugated steel profile is also suitable for culverts underneath railway tracks», observes Lüthi. The project now moves on to the next phase.